Front

Front

Side

Side

According to different requirements, such as weight or cost, etc., to choose a different design. Chassis, for example.

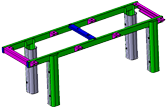

| Structure | Picture | Weight | Cost |

|---|---|---|---|

| Steel welding chassis |

|

1st. (heaviest) |

3th. |

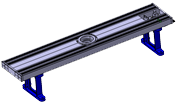

| Aluminum beam+Die casting seat leg |

|

2nd. | 2nd. |

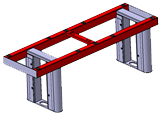

| Aluminum alloy welding chassis |

|

3th. |

1st. (cheapest) |

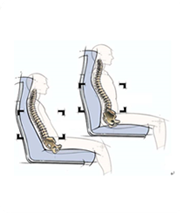

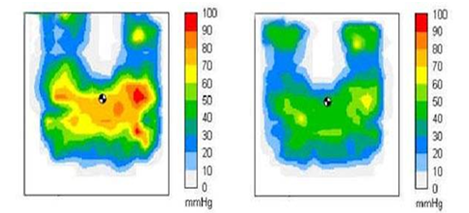

Ergonomics simulation analysis

The commonly used fire resistant standards can be tested on our seats, such as DIN5510-2,FAR25.853,BSS7238,BSS7239,TB/T3237

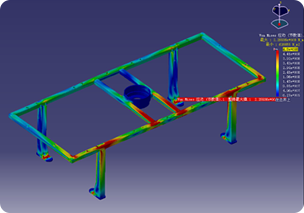

Static strain testing system

Mechanics experiment simulates the real strained condition to determine the strength, stiffness and stability of the product under static load

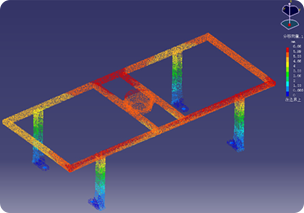

High frequency vibration system

It simulates the vibration environment in the running process of high speed train, determine the seat actual state of train operating environment

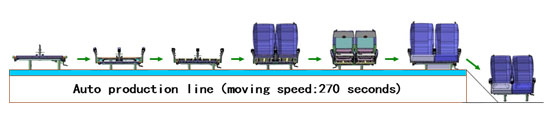

In order to carry out “One Flow “production, we engineering analysis for each working step on each single seat, then calculate capacity and speed.